Pressure Rated HDPE Water Pipe

When it comes to water distribution, strength and dependability are key. Our Pressure Rated HDPE (High-Density Polyethylene) Water Pipe delivers both in spades. Designed to handle high-pressure systems with ease, this pipe is built tough to withstand the most demanding applications. Whether it’s potable water, irrigation, or industrial use, our HDPE pipe ensures long-lasting performance without compromising on safety or efficiency.

- Home

- /

- Pressure Rated HDPE Water Pipe

Durability That Lasts: Resistant to corrosion, chemicals, and environmental factors, our HDPE pipe stands the test of time, providing a reliable solution that won’t degrade in tough conditions. Its superior flexibility means fewer joints, reducing the risk of leaks and lowering installation costs.

Effortless Installation: Lightweight and flexible, HDPE pipe is easier to handle, transport, and install compared to traditional materials. Its innovative design allows for quick and cost-effective setups in any terrain, from rural water systems to urban infrastructure.

Pressure-Rated for Tough Conditions: Engineered to meet the highest standards for pressure resistance, our HDPE water pipe guarantees safe water flow even under extreme conditions. Designed for both high-pressure and low-pressure systems, it’s the ideal choice for projects that demand strength and reliability.

Trust our Pressure Rated HDPE Water Pipe to deliver safe, sustainable, and cost-effective water solutions for any application. When performance matters, HDPE delivers!

Characteristics and Advantages

Manning Coefficient (n) = 0.009 Hazen-Williams Coefficient (c) = 150

-

Potable Water Distribution: HDPE pipes are widely used for transporting drinking water in both urban and rural water supply systems due to their non-toxic, corrosion-resistant properties.

-

Irrigation Systems: Ideal for agricultural and landscape irrigation, HDPE pipes can withstand varying water pressures and are resistant to chemicals and fertilizers.

-

Municipal Water Infrastructure: These pipes are commonly employed in city water mains, service lines, and other infrastructure for their ability to handle high-pressure water flow and resistance to corrosion.

-

Sewage and Wastewater Systems: HDPE pipes are often used in sewage and wastewater applications due to their strength, flexibility, and ability to resist leaks and root intrusion.

-

Industrial Water Systems: In industrial settings, HDPE pipes are used for transporting water in cooling systems, processing plants, and manufacturing facilities, handling both high pressure and demanding conditions.

-

Fire Protection Systems: Due to their pressure rating and durability, HDPE pipes are used in underground piping systems for fire hydrants and sprinkler systems.

-

Stormwater Drainage: These pipes are used in stormwater management and drainage systems, ensuring efficient water movement and long-lasting performance, even in extreme weather conditions.

-

Mining and Slurry Systems: HDPE pipes are perfect for transporting water and slurry in mining operations due to their ability to handle abrasives and resist chemical corrosion.

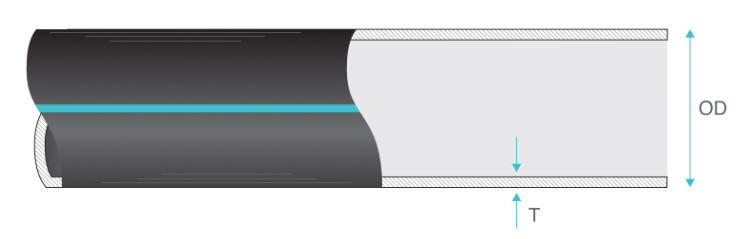

Availability in diameters from 1/2″ to 36″. We operate in Type I (controlled internal diameter) in 1/2″ and 3/4″ for home outlets. The rest is handled in Type II (controlled outside diameter) from 1/2″ to 36″.

In sections it is handled from 2″ to 36″ in lengths of 20 and 40 feets. Rolls in presentations of 330 and 500 feets in diameters from 1/2″ to 3″, for 4″ diameter only rolls of 330 feets in SDR 11, 9, 7.3 and 7.

Some SDR are not handled in certain smaller diameters (see attached table). Consult your advisor about special lengths.

Outside Diameter

PSI199 IN

PSI157 IN

PSI142 IN

2.7

PSI128 IN

PSI100 IN

PSI85 IN

PSI57 IN

PSI43 IN

WARRANTY

PlumGenex warrants that the pipe products are manufactured according applicable ASTM, ANSW/AWWAand ANSI/NSF standards and are free from defects in workmanship and materials.

QUALITY CONTROL

Physical properties (or chemical) of PlumGenex products described represent average values obtained according acceptable test methods and are subjeted to normal manufacturing variations.

Get a quote

We are always here for you day or night. PlumGenex understands the importance in making sure you and your customers get exactly what you want, when you want. So we make sure your stock order gets expedited effortlessly.

Phone

+1 (530) 615-6400

Products

Company

PlumGenex

Reno, NV, USA