PVC

C900

PVC C900 is a specific type of PVC (polyvinyl chloride) pipe that follows the American Water Works Association (AWWA) standard for water transmission and distribution.

PlumGenex PVC C900 pipes are recognized for their durability, high-pressure capacity, and adherence to stringent industry standards. They play a critical role in ensuring safe and efficient water transmission and distribution across various sectors, contributing to reliable water infrastructure.

Common Applications

Water Mains, Infrastructure Development, Industrial Usage, Industrial Water Supply, Chemical Processing, Construction Projects, Infrastructure Expansion, Treated Water Transpor, Reservoirs and Storage, Agricultural Water Distribution, Commercial Buildings, Residential Infrastructure.

Product Specifications

All pipe is made from quality PVC resin, compounded to provide physical and mechanical properties that equal or exceed cell class 12454 as defined in ASTMD1784. The pipe is suitable for use as pressure conduit. Provisions must be made for expansion and contraction at each joint with an elastomeric gasket. The bell consist of an integral wall section with a factory installed elastomeric gasket, which meets the requirements of ASTM F477. The bell section is designed to be at least as hydrostatically strong as the pipe barrel and meet the requirements of AWWA C900. The joint design meets the requirements of ASTMD3139. Sizes and dimensions shall be as shown in this specification

Randomly selected specimens tested according ASTM D1599 shall attain pressure values shown within 60-70 seconds

Engineered for Superior Pressure Handling: PVC C900 pipes are purpose-built for high-pressure water transmission and distribution. Designed to handle substantial pressure demands, they stand as the epitome of reliability in water systems.

Unmatched Strength, Varied Classes: Available in a range of classes, each denoting specific pressure ratings and wall thicknesses. Whether it’s Class 150 or higher, these pipes provide the resilience needed for diverse high-pressure applications.

Corrosion-Resistant, Long-Lasting: Crafted from top-quality PVC material, these pipes boast exceptional corrosion resistance and durability. They’re engineered to withstand the test of time, ensuring long-term reliability in water distribution networks.

Municipal Water Solutions: Trusted by municipalities, these pipes play a pivotal role in delivering safe, potable water from treatment plants to homes, businesses, and communities. They’re the backbone of secure water distribution systems.

Industrial Powerhouses: From industrial complexes to manufacturing facilities, PVC C900 pipes offer the strength and reliability required for high-pressure water supply lines in industrial settings.

Infrastructure Marvels: Vital components of water infrastructure projects, these pipes serve as the backbone of water mains and underground utilities. Their robustness ensures uninterrupted water flow in critical infrastructure.

Compliant and Reliable: Built in accordance with AWWA standards, PVC C900 pipes meet stringent quality requirements. They ensure compliance and reliability, meeting or exceeding expectations in water supply projects.

DIMENSIONS CLASS 165 (DR-25)

DIMENSIONS CLASS 235 (DR-18)

MEETS AWWA C900<br /> PVC C.I.O.D. Distribution Pipe<br /> Pressure Class 165 and 235 psi

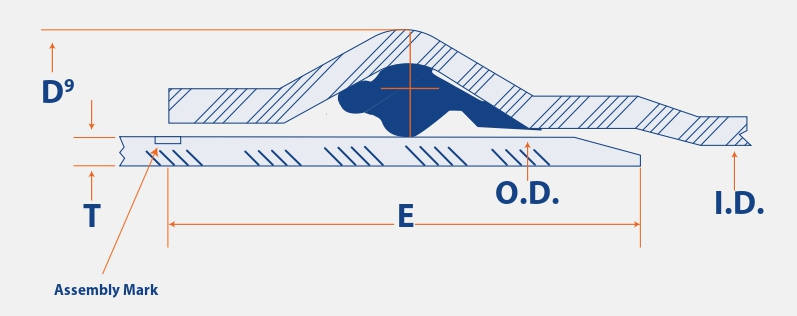

D9

Bell Outside Diameter

E

Distance Between Assembly Mark to the End of SPigot

I.D.

Inside Diameter

T

Wall Thickness

O.D.

Outside Diameter

WARRANTY

PlumGenex warrants that the pipe products are manufactured according applicable ASTM, ANSW/AWWA and ANSI/NSF standards and are free from defects in workmanship and materials.

QUALITY CONTROL

Physical properties (or chemical) of PlumGenex products described represent average values obtained according acceptable test methods and are subjeted to normal manufacturing variations.

Get a quote

We are always here for you day or night. PlumGenex understands the importance in making sure you and your customers get exactly what you want, when you want. So we make sure your stock order gets expedited effortlessly.

Phone

+1 (530) 615-6400

Products

Company

PlumGenex

Reno, NV, USA